Introducing the Knight Shade! An exterior motorized screen for the world’s best screen and patio dealers.

Custom manufactured to your exact specifications: just-in-time and just-for-you. Templar Screens’ Knight Shade was designed from the ground up to be flexible enough to match any home design, reliable enough for the most discerning contractor and priced effectively to help you win more jobs.

Features Include:

Seamless surface mount retention tracks – no ugly cord-channel covers or extra visible seams. 2.00″ wide track, to make your in-the-field deductions easy.

Each Knight Shade is powdercoated and built just-in-time and just-for-you. 12 “standard” frame colors and 4-5 seasonal colors always in stock, and every RAL and powder option available at your request. Every extrusion is powdercoat AFTER being cut to length, so even the cut ends are powdercoated – preventing a common cause of powdercoat failure and eliminating service calls.

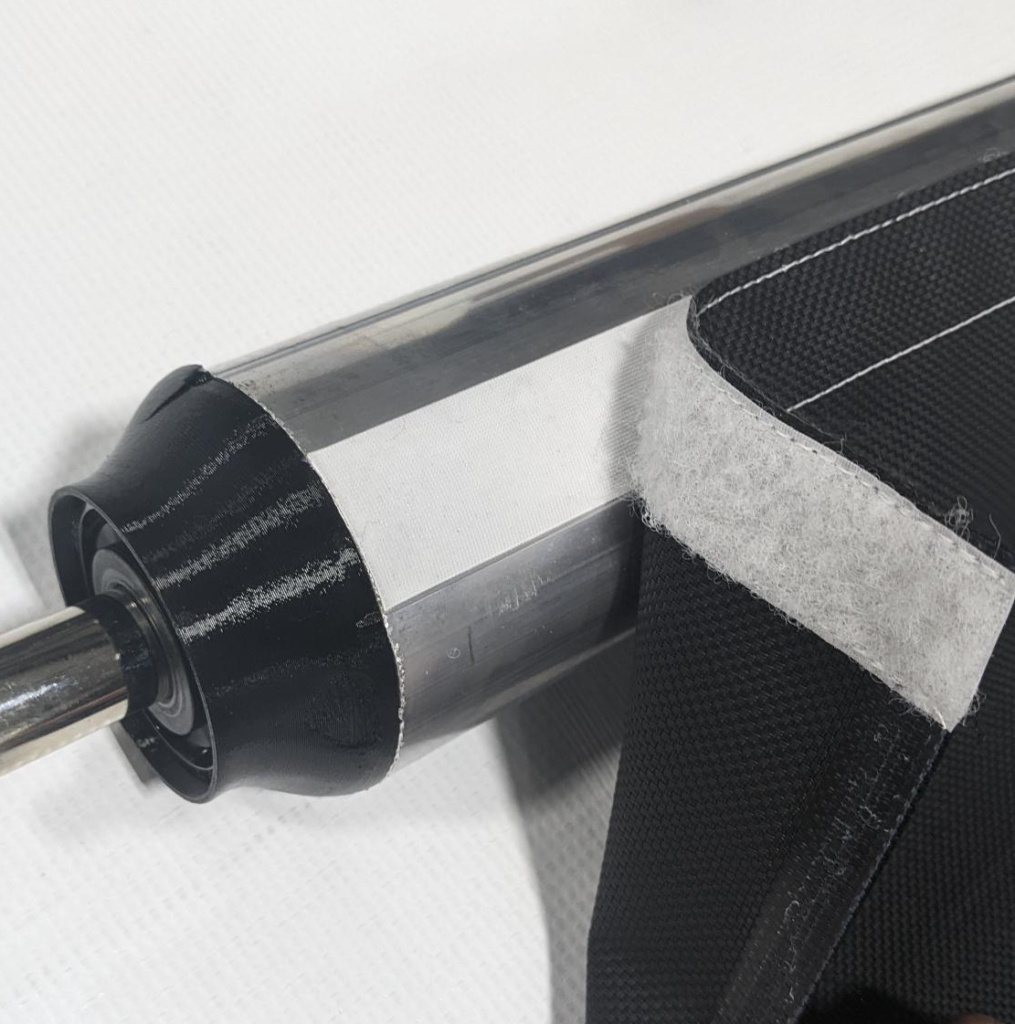

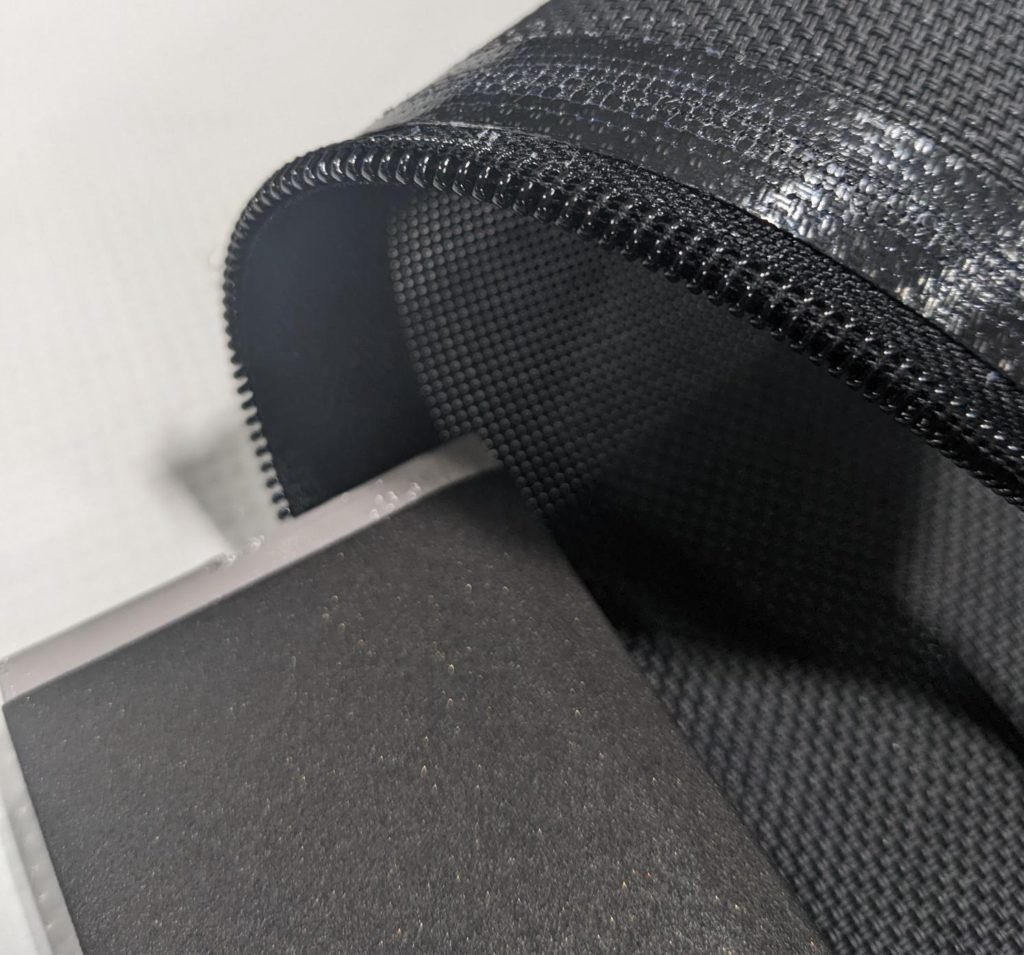

Hook and loop roller tube attachment provides infinite adjustability for your installers in the field. Account for uneven surfaces and strange skews by adjusting the attachment until it’s picture perfect. No more wrinkles or “hour-glassing”. (Fair warning: if you’ve never installed this method you’re probably going to mutter some obscenities during your first install. But after a few jobs, you won’t ever want to go back.)

Industrial grade FDM 3D Printed Parts. Zero draft = Perfect fit! Our parts have geometry that would be impossible with traditional plastic injection molding and use material that is natural UV-resistant. Each part is printed in a kit just-in-time for each specific Knight Shade – allowing us to carry nearly zero inventory and keep overhead costs low.

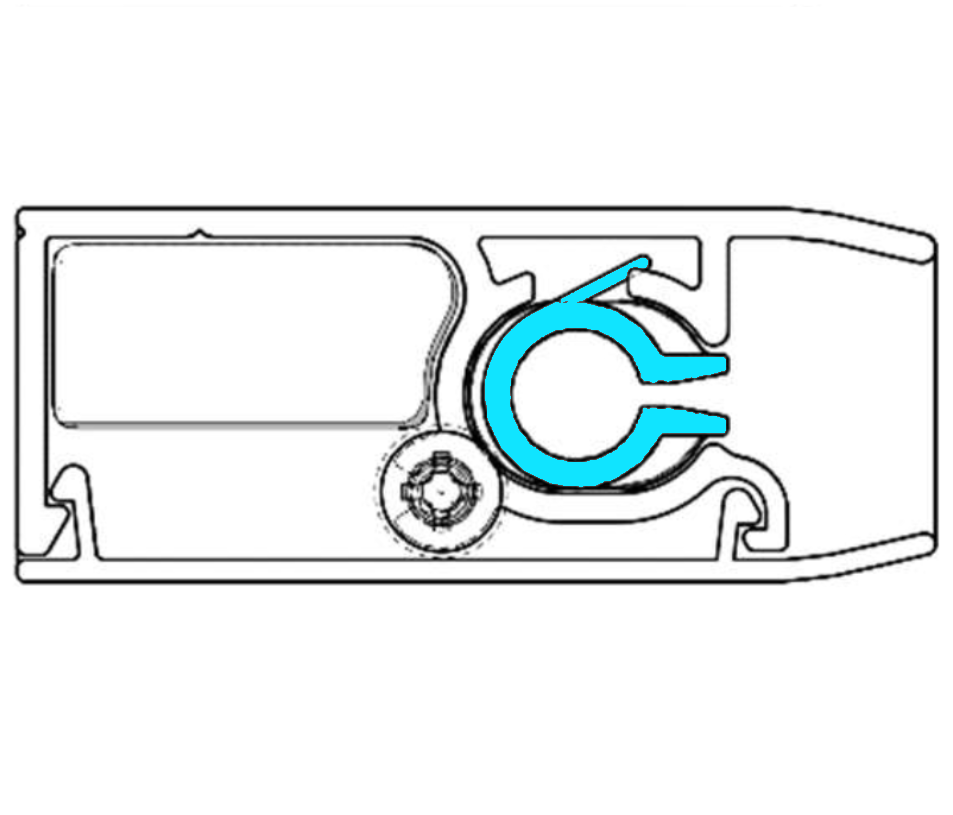

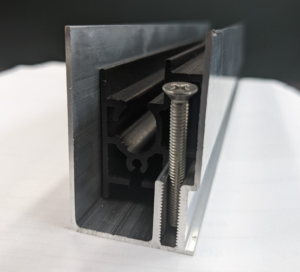

Flexi-Track dual material PVC zipper retainer. Entirely encapsulated by thick aluminum extrusion, yet designed to give you some adjustment during installation. 1/8″ of automatic “flex” available on each side. Our track systems combine Rigid PVC, Semi-Rigid PVC, PETG and 6061-T6 Aluminum to give you strength where you need it while allowing the screen to deploy with a buttery smoothness. This is what best-in-class looks like.

Extruded threads allow for complete flexibility in recessed track mounting alignment. Adjustment holes are pre-drilled on the “inner track” before powdercoating, but the extruded threads along the length of the track mean that any outer track can be used with any inner track, making your installers life that much easier.

Sixteen custom aluminum extrusions allow you to customize a Knight Shade for any and every install. ALL extrusions come from North America with alloy/temper combinations chosen to minimize deflection.

#7 Zippers impulse welded on all retention edges. No sewn seams to fail or compromise the fabric panel. Our welds are tested and recorded daily to ensure the fabric coating fails before the weld does! Using a zipper for side retention allows for a tight coil inside the upper housing and a greater unit height. Combined with our flexi-track system, the Knight Shade is ridiculously strong.

Dependable motors and control options with the home owner in mind. We offer both Alpha Pro (7-year warranty) and Somfy Altus (5-year warranty) motors in different configurations depending on your requirements.

And more…

- Silent Idler pin with bushings.

- Double-brush integrated fabric cleaning built into the housing.

- Naturally scalloped tube end fittings to provide room for “zipper build-up”, while perfectly cradling the fabric.

- All Stainless Steel fasteners.

- Durable packaging, to get the screen to your in one piece.

- Reliable warranty backed by folks who care.

A Good Process!

It’s not just what your screen looks like, it’s how it’s made that counts. With every step given great care, your customers are going to love their product.

- Each screen is individually powdercoated to your color specifications. To ensure quality, we’re the only screen manufacturer the tests each Knight Shade’s powdercoat surface (to European Standard BS EN 12206-1:2004) standards and sends you the test card with each order.

- All our zipper retention edges are welded without any sewn stitches.

- Double axis CNC-cut fabric panels, with 0.01″ accuracy off the table. Perfectly square cuts on each panel!

- Single axis CNC for all aluminum extrusion cuts. All the human elements removed from measuring side, so our folks can focus on excellent quality, every time.

- (Warning: Manufacturing Nerd Alert….) To keep our industry-leading lead times, we designed our factory to put your product straight from powdercoating oven right into it’s packaging. That’s right, we don’t have assembly tables for stuff to just sit around on – taking up time and getting scratched.

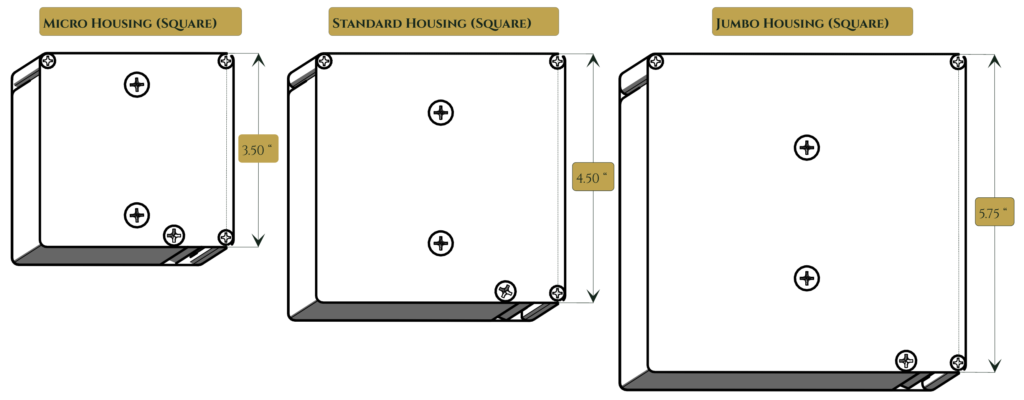

| Micro Housing | Standard Housing | Jumbo Housing | |

|---|---|---|---|

| Size | 3.50″ Square | 4.50″ Square | 5.75″ Square |

| Width Limit | 12 feet | 18 feet | 25 feet |

| Height Limit | 7 feet | 12 feet | 20 feet |

Explore the Knight Shade:

Composer Export if(typeof(top) != “undefined”) { top.ShowPaper = ShowPaper; } function ShowHotSpot(evt,hotspotid) { var svgDocument = evt.target.ownerDocument; var strId = “hotspot.”+hotspotid; var hotspot = svgDocument.getElementById(strId); if(hotspot) hotspot.setAttribute(“opacity”,”.5″); } function HideHotSpot(evt,hotspotid) { var svgDocument = evt.target.ownerDocument; var strId = “hotspot.”+hotspotid; var hotspot = svgDocument.getElementById(strId); if(hotspot) hotspot.setAttribute(“opacity”,”0″); var toolTip = svgDocument.getElementById(‘ToolTip’); if(toolTip) toolTip.setAttribute(“visibility”,”hidden”); } function ShowToolTip(evt,hotspotid,strTooltip) { if(strTooltip==””) return; // change text var svgDocument = evt.target.ownerDocument; var tiptext = svgDocument.getElementById(‘ToolTipText’); if( !tiptext ) return; tiptext.firstChild.nodeValue = ” ” + strTooltip + ” ” ; // show tooltip before, else some refresh issue var toolTip = svgDocument.getElementById(‘ToolTip’); if(!toolTip) return; toolTip.setAttribute(“visibility”,”visible”); toolTip.setAttribute(“opacity”,”.95″); // move tooltip // get viewbox var root = svgDocument.documentElement; var vbox = (root.getAttribute(“viewBox”)).split(‘ ‘); var x0 = parseFloat(vbox[0]); var y0 = parseFloat(vbox[1]); var vboxW = parseFloat(vbox[2]); var vboxH = parseFloat(vbox[3]); // get default width of svg var strW = root.getAttribute(“width”); var svgW = parseFloat(strW); if(strW.indexOf(‘mm’) != -1) svgW *= 3.779; var strH = root.getAttribute(“height”); var svgH = parseFloat(strH); if(strH.indexOf(‘mm’) != -1) svgH *= 3.779; // 96 dpi -> 96/25.4 = 3.779 // update the viewbox / width / height if svg is embedded in html with zoom fit all var realx0 = x0; var realy0 = y0; var realvboxW = vboxW; var realvboxH = vboxH; var realsvgW = svgW; var realsvgH = svgH; if ((typeof(top) == “undefined”) || (typeof(top.svgctl1) != “undefined”)) // embedded in html { // get window size in pxl svgW = window.innerWidth; svgH = window.innerHeight; // calculate real viewbox realsvgW = svgW; realsvgH = svgH; if((svgW / svgH) > (vboxW / vboxH)) { realvboxW = (vboxH * svgW) / svgH; realvboxH = vboxH; realx0 = x0 – (realvboxW – vboxW)/2 ; } else { realvboxH = (vboxW * svgH) / svgW; realvboxW = vboxW; realy0 = y0 – (realvboxH – vboxH)/2 ; } } // get user zoom/pan var newScale = root.currentScale; var translation = root.currentTranslate; // transform pxl to user unit var xPos = (((evt.clientX+10- translation.x)/newScale) * realvboxW)/realsvgW + realx0 ; var yPos = (((evt.clientY+5- translation.y)/newScale) * realvboxH)/ realsvgH + realy0 ; var scaleForWidth = ( (1 / newScale) * realvboxH) / realsvgH; // move tooltip toolTip.setAttribute(“transform”, “translate(” + xPos + “,” + yPos + “)” ); // resize tooltip var fontsize = 12; tiptext.setAttribute(“font-size”,fontsize*scaleForWidth); tiptext.setAttribute(“y”, fontsize*scaleForWidth); var tipBG = svgDocument.getElementById(‘ToolTipBG’); var outline = tiptext.getBBox(); if(tipBG) { tipBG.setAttribute(“stroke-width”, 1*scaleForWidth); tipBG.setAttribute(“width”, Number(outline.width) ); tipBG.setAttribute(“height”, Number(outline.height) + fontsize*.5*scaleForWidth ); } var ToolTipShadow = svgDocument.getElementById(‘ToolTipShadow’); if(ToolTipShadow) { ToolTipShadow.setAttribute(“width”, Number(outline.width) ); ToolTipShadow.setAttribute(“height”, Number(outline.height) + fontsize*.5*scaleForWidth ); ToolTipShadow.setAttribute(“x”, 3*scaleForWidth); ToolTipShadow.setAttribute(“y”, 3*scaleForWidth); } } function ShowPaper() { var svgDocument = getDocument(); var paper = svgDocument.getElementById(“paperID”); if(paper) { paper.setAttribute(“transform”,”scale(1)”); paper.setAttribute(“opacity”,”1″); paper.setAttribute(“visibility”,”visible”); } var svg = svgDocument.getRootElement(); if(svg) { svg.setAttribute(“width”,”235.000mm”); svg.setAttribute(“height”,”300.000mm”); svg.setAttribute(“viewBox”,”-5.000000 -5.000000 235.000000 300.000000″); } } Surface, inset and recessed options available.Available in three heights.14Available in three sizes.32IDAssembly Description1Fabric and Hem Bar Assembly2Housing AssemblyIDAssembly Description3Motor Tube Assembly4Retention Assemblytooltip